Parachute Packing

Back Pack, Seat Pack, Headbox, Drogue,

and Deceleration (Drag) Chutes

Task Aerospace inspects and packs a wide variety of parachutes used in several ejection seat types and aircrafts.

Parachute Systems Serviced by Task Aerospace, Inc.:

- BA-22 Back Pack Parachute

- SA-20 Seat Pack Parachute

- NES-12 Back Pack Parachute

- NES-25 Back Pack Parachute

- MB MK-59A Head Box Parachute

- Alpha Jet SIIIS Head Box & Drogue Parachute

- Drogue Parachutes

- Deceleration (Drag) Parachutes

PARACHUTE PACKING PROCESS

- Parachute packing tables are 56’ long

- They are covered in a soft, pliable rubber material to prevent damage to parachute

- Parachute is laid out, inspected, and re-packed in accordance with appropriate technical orders. Any issues or damage is immediately brought to customers attention.

- A Certificate of Conformance is provided

- Task maintains records of the parachutes and notifies the customer when the next repack event is approaching

- Task inventories a selection of spare parts (Including SCOT Automatic Parachute Ripcord Releases and Emergency Bail Out Oxygen Bottles)

- Procurement of replacement parts or spares, including personal locator beacons

- Task utilizes 2 riggers, one being a FAA Certified Master Rigger

- Task has the ability to test SCOT Automatic Parachute Ripcord Releases using the calibrated SCOT Automatic Parachute Release Tester

- Refurbishment of Ballistic Spreading Gun

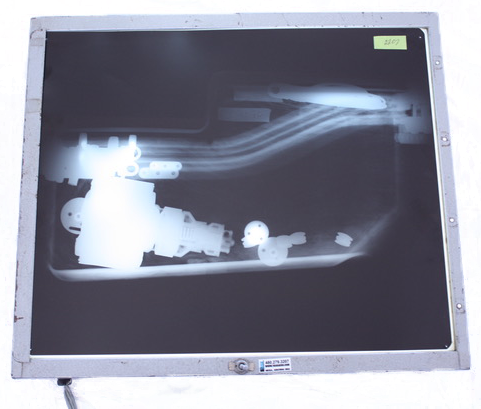

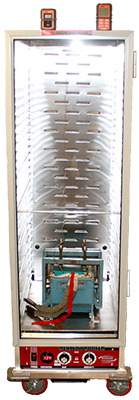

Stencel SIIIS Head Box Parachute placed in oven for 12 hours in accordance with technical order.

Packing includes includes the Stencel SIIIS ejection seat currently in the Alpha Jet and Harrier aircrew escape systems. The emergency parachute system consists of the headrest assembly with emergency parachute, a spreader gun, the drogue chute and drogue chute container, as well as the harness.

The headbox-packed parachute is a unique parachute system that requires repacking every 6-months (180 days) per the Technical Documentation for the operation of the aircraft. The canopy is the C-9, 28 foot round nylon canopy with 28 shroud lines, part number 472P211E001-1. The canopy is packed onto the headbox with its pyrotechnically actuated spreader gun. The spreader gun allows for slow speed low altitude egress, making the canopy inflate very quickly. The pyrotechnic device in the spreader gun also has a shelf-service life that requires it be changed out every 17 years, and a service life of 8.5 years. The canopy and spreader gun are packed into the very small space of the headbox by trained technicians using unique tooling and unique capabilities to handle the explosive spreader gun.

USERS ARE CAUTIONED THAT THE LOADED SPREADER GUN IS AN EXPLOSIVE DEVICE MUCH LIKE A GRENADE WITH ELEMENTS THAT RADIATE 360 DEGREES WHEN FIRED. THIS LANYARD FIRED DEVICE IS VERY DANGEROUS.

Task has full capabilities to overhaul the spreader gun per our BSG overhaul procedures using the proper NAVAIR technical documents.

The drogue chute has a Ribless Guide Surface Canopy made up of Kevlar fabric and also has a 6-month (180 day) repack cycle. The drogue chute is also packed into a very small container utilizing special tooling and methods by trained Task technicians.

The Alpha Jet parachute, spreader gun, and drogue chute systems are packed into a very compact configuration that require extensive special tooling and special training. Task personnel are trained on parachute systems, packing, and handling of the explosive components. The parachute, spreader gun, and the drogue chute are packed into a small hard shell container through a process requiring several cycles of compression in a unique packing fixture.

Task can provide you with current parachute packing, drogue chute packing, and the pyrotechnic devices. A user will simply send the parachute and container to Task in Mesa Arizona. Turnaround time is surprisingly short.

For more information, contact Tony Nikopoulos.